BACK IONIZATION

- What is it - Back Ionization happens when the surface being powder coated has too much electrostatic charge and doesn't have any more room to accept newly charged particles, or ions.

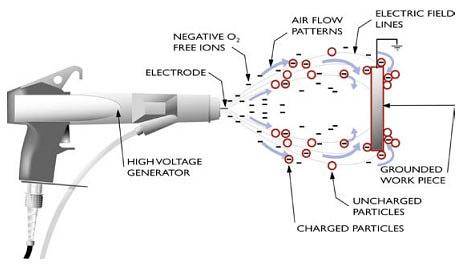

- Why does it happen - Negative Charged Free Ions leave the powder gun and are looking for a grounded surface to adhere to. If the part that is being coated already has a coat of powder on it, such as a re-coat or a part that has been primered, those free ions will repel off of the part (almost as if there is no room for them there and they have to find a new home)! Because this happens AFTER powder has already been applied to your part, this creates a rough & uneven finish that looks much like "craters" or "pinholes".

- What you can do - Most powder guns are available with an ion collection device which grabs these ions before they get onto your part. These devices are called different things, depending on who the manufacturer is and what powder gun they fit, but they all do the same thing....to grab the charged ions as they exit the gun. We are Wagner powder coating distributors and carry the full line of Wagner Manual Powder Coating Equipment and Back Ionization Assemblies.

CONTACT US to learn more about the Powder Coating process and how we can help!